Traditional Overlapping

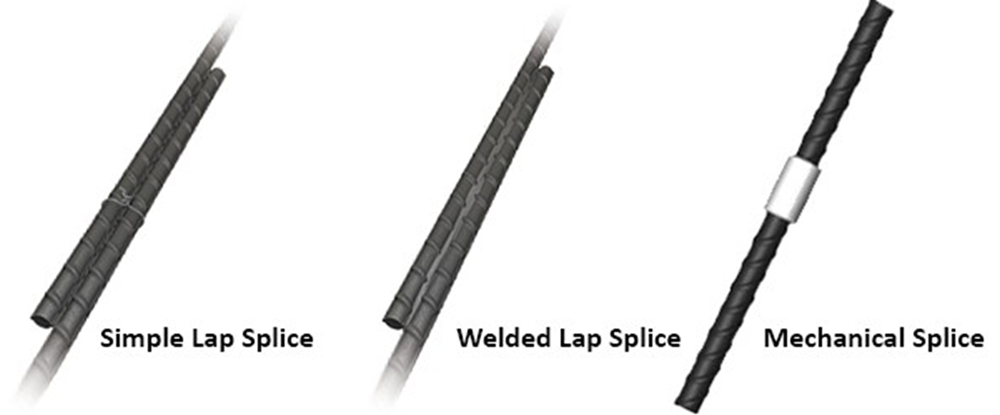

Overlapping involves placing two rebars side by side for a certain length to ensure they are effectively bound together once encased in concrete.

Pros:

- Universality: Requires no specialised equipment. The technique is well-known and understood universally.

- Cost-Effective: Initially, the overlapping method might seem cheaper as there’s no need for additional components.

Cons:

- Material Consumption: Overlapping demands extra rebar length which can lead to increased material costs, especially in large-scale projects.

- Size Issues: As the diameter of the bars increases, the required overlap length also increases, which might not be feasible in all designs.

- Less Seismic Resistance: Overlapped joints are sometimes less effective in areas prone to earthquakes.

- Inconsistent Quality: The strength of the joint relies heavily on the workmanship.

Rebar Couplers

Rebar couplers are mechanical devices used to join two lengths of rebar. They create a solid joint, eliminating the need for overlapping.

Pros:

- Uniform Diameter: Using couplers ensures that the diameter remains consistent without the additional bulge from overlaps.

- Material Savings: As there’s no need for overlapping lengths, material consumption is reduced.

- Increased Strength: Provides full strength in tension, compression, and stress reversal applications.

- Seismic Benefits: Offers better performance in seismic-resistant structures.

- Space Saving: Especially important in designs where space is a constraint, as couplers take up less room than overlaps.

- Quality Control: Ensures consistent and predictable structural integrity.

Cons:

- Initial Cost: The initial investment for couplers might be higher.

- Specialised Training: Workers need training to install couplers, which can be an added time and cost.

So, Which One to Choose?

The decision between overlapping and rebar couplers largely depends on the specific requirements of a project. If you’re working on a large-scale project where material saving is crucial, or in regions where seismic activity is a concern, rebar couplers may offer clear advantages. However, for smaller projects or in situations where initial costs need to be minimised, overlapping might be preferred.

It’s worth noting that as construction standards evolve, the focus on quality, safety, and efficiency will likely make modern methods like rebar couplers more prevalent. Consulting with structural engineers and experts is always advisable to make an informed choice tailored to the needs of each construction endeavour.

While the traditional overlapping method has its own set of advantages and has served the construction industry well for years, rebar couplers present a modern, efficient, and often more structurally sound alternative. As with any technological evolution, it’s about weighing the pros and cons and choosing what’s best for the task at hand.