Benefits of Rebar Couplers Over the Overlapping Method

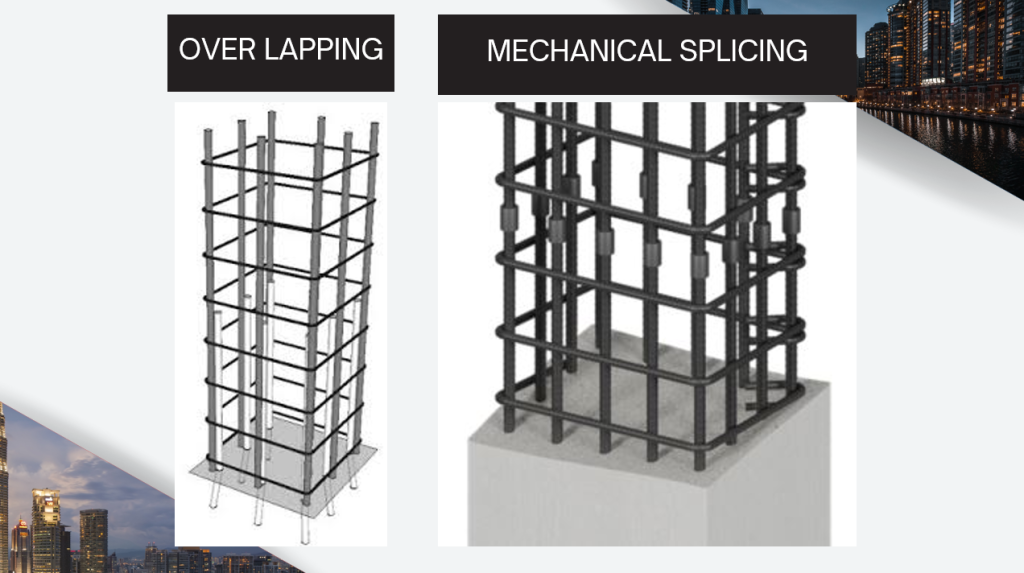

Overlapping Method:

1. Requires extra rebar length (50× bar diameter), increasing steel usage.

2. On the running site, Precise cutting leads to scrap and more wastage.

3. Bending and tying rebar is labor-intensive.

4. Weakens under high stress due to concentrated loads in structures.

5. Creates congestion in beam-column joints.

Mechanical Splice Coupler Method:

1. Eliminates overlap; saves material with precise bar lengths.

2. Connect bars directly, minimizing steel waste.

3. Streamlines the process, reducing labor time and costs.

4. Provides stronger, safer joints that meet global standards.

5. Simplifies reinforcement placement and improves concrete compaction.

Construction Project for Example:

For the Overlap method with TMT BAR 16 MM Dia.,

For a 16 mm diameter rebar with a 50 x Overlap, the additional length =

50 × 16 = 800 mm (0.8 m)

Overlap Length: 0.8 m

Cross-Sectional Area:

A= π × (d/2)2 = π × (0.016/2)2 = 0.000201 m2 where (Diameter of Rebar (d): 16 mm = 0.016)

(Formula is, Steel Weight = Length × Cross – Sectional Area × Density of Steel)

Steel Weight for joint = 0.8 m × 0.000201 m2 × 7,850 kg/m3

Steel Weight for single joint = 1.26 Kg

So, The steel weight for a single overlapping joint of a 16 mm diameter TMT bar is approximately 1.26 Kg

Steel cost per kg = 51 Rs. including Binding Wire Labor cost for single overlap = 55 Rs.

Cost per overlap = 1.26 x 55 = 69.3 Rs.

—————————————————————————————————————-

For Mechanical Splice Method for Rebar Coupler Size Ø 16 MM,

16 MM Rebar Coupler Weight/Piece = 0.10 Kg

for 1000 joints couplers all total wight will be 100 Kg.

Coupler Cost = 20 Rs. (EN Steels -High Carbon Alloy steels)

Labor Cost = 45 Rs. (Rebar Threading cost only)

Cost per Single Mechanical Splice = 55 Rs.

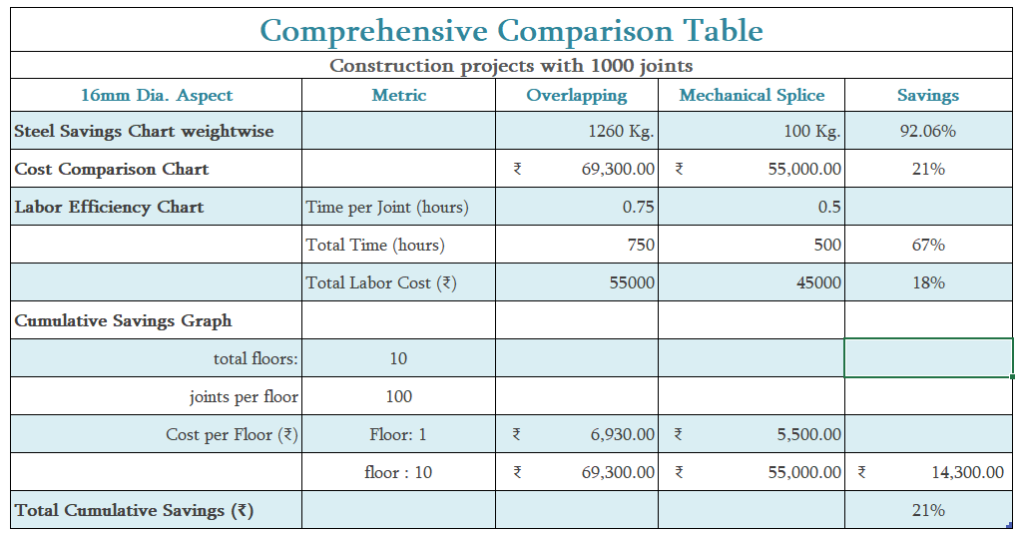

Consider a project with 1,000 joints for High -Rise Building:

Overlap Steel Weight: 1.26 x 1000 = 1260 Kg

Mechanical Splice Coupler Steel Weight: 0.10 X 1000 =100 kg

Waste of steel in Weight = 1260 – 100 = 1160 Kg.

Saving Steel weight in percentage = (1260 – 100)/1260 x 100 = 92.06%

As you can see,

Steel Savings: Overlapping will be used already 90.9 kg Approx. min. extra steel.

Labor Savings: Couplers save significant labor by eliminating bending and tying.

Structural Integrity: Couplers ensure stronger and safer joints.

Space Optimization: Couplers prevent congestion in beam-column intersections.

Summary of Costs:

Overlapping cost total = 69.3 x 1000 = 693000 Rs.

Mechanical Coupler Splice cost = 55 x 1000 = 55000 Rs.

Saving project cost = 63,8000 Rs.

Saving cost in percentage = [(693000 – 638000) / 693000] x 100 = 21 %