Rebar couplers, or mechanical splices, are increasingly being recognized as a critical component in the construction industry. Serving as an innovative alternative to lapping and welding, rebar couplers are gaining traction for their efficacy in ensuring structural integrity, optimising design, and even promoting sustainable construction practices. Here’s a deep dive into how and where they’re being utilised in contemporary structures around the world.

What are Rebar Couplers?

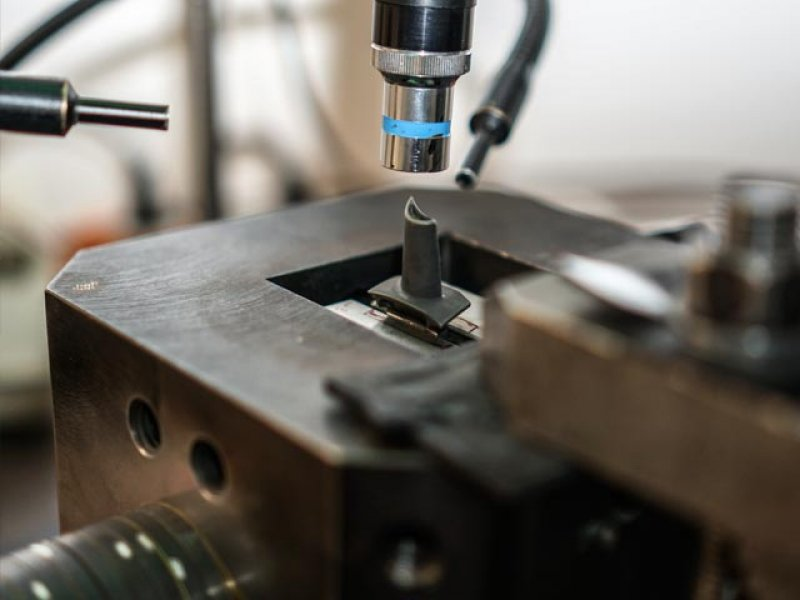

Rebar couplers are mechanical devices that connect two pieces of reinforcing steel bars (rebar), creating a point of load transfer between them. Traditionally, rebars were overlapped or lapped, a process which consumes more space, uses more materials, and may not ensure optimal load transfer. The introduction of couplers has revolutionised this, making connections more robust, more efficient, and often more economical.

Key Benefits

- Structural Integrity: By ensuring a direct load path between connected rebars, couplers provide a more consistent and reliable connection than lapping.

- Space Savings: Eliminating the need for overlapping rebars can save significant space, especially in densely packed concrete areas.

- Material Efficiency: Reduction in the length of overlap leads to reduced rebar quantities, thus lowering costs and promoting sustainability.

- Design Flexibility: As overlapping is not required, architects and engineers have more flexibility in design, especially in congested areas.

Applications in Modern Construction

- High-rise Buildings: In cities that are expanding vertically, like Dubai, Shanghai, or New York, space is a prime concern. High-rise buildings, with their dense structural requirements, benefit immensely from rebar couplers, which optimise space and ensure robust connections between rebars.

- Infrastructure Projects: Whether it’s the sprawling bridges of San Francisco or the vast tunnels under the English Channel, modern infrastructural wonders rely on rebar couplers for ensuring that structural elements remain tightly connected, especially under dynamic loads.

- Earthquake-Resistant Structures: In seismic zones such as Japan or parts of California, building structures that can withstand the forces of earthquakes is crucial. Rebar couplers ensure continuity in reinforcement, a key component in the design of seismic-resistant structures.

- Retrofitting and Renovations: For structures that are being updated or expanded, integrating new reinforcement with the old can be a challenge. Rebar couplers provide a seamless way to connect old and new rebars, ensuring structural integrity.

- Nuclear Power Plants: In places where safety is paramount, such as nuclear facilities, rebar couplers play a vital role. They ensure that the reinforced concrete structures within these plants have maximum structural integrity, thus safeguarding against potential hazards.

- Offshore and Marine Structures: Structures in marine environments, like ports, piers, and offshore platforms, are exposed to corrosive elements. Rebar couplers reduce the exposed surface area of the rebar, which in turn can help in reducing potential corrosion points.

Global Trends

Globally, there’s a palpable shift towards sustainable and efficient construction practices. This means minimising waste, reducing the carbon footprint, and ensuring longevity of structures. In this context, rebar couplers are finding increased acceptance. Countries with burgeoning infrastructural development like India, China, and parts of Africa are adopting rebar coupler technologies not just for their obvious structural benefits, but also for their role in promoting sustainable construction.

Rebar couplers are undoubtedly a game-changer in the realm of modern construction. Their role in promoting structural integrity, design flexibility, and sustainability makes them an indispensable asset in contemporary structures. As the construction industry continues to evolve and prioritise both innovation and sustainability, the significance of rebar couplers is poised to grow even further.